offer maximum computing, system and graphics performance

for high-speed processing of large volumes of data.

offer a high-quality, industrial design:

- Full-metal enclosure with high electromagnetic compatibility

- High level of dust protection and low noise generation through fan-controlled overpressure ventilation

- Continuous operation at ambient temperatures up to 40 °C (104 °F), at maximum configuration and without loss of power (throttling)

and integrated interfaces

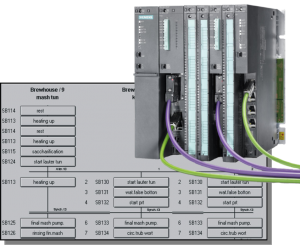

make the SIMATIC S7-400 process controller

ideal for scaling up your BRAUMAT PCS

as your production needs to grow.

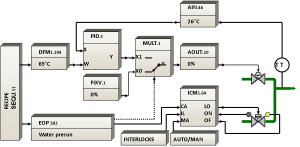

to Modular Software Design

BRAUMAT™ provides a structured, modular design approach,

down to the PLC code.

BRAUMAT Features

On the other hand, control tasks are carried out by the SIMATIC S7-400 PLCs. From a process control perspective, IOS-Servers only require connection to the PLC when starting a new production recipe. When a new recipe is started, it is downloaded into the PLC, after which it runs independently from the IOS-Server.

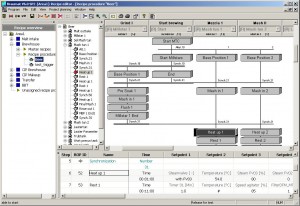

A Graphical Recipe Management System allows creating and testing recipes for new brands, fast and easily. Brewing experts will be able to modify and adapt processing sequences and parameters such as volumes, temperatures and time intervals, without the need for a software engineer. And what’s more, the system allows for quick adjustments to changes in production requirements, at any time, without the need to interrupt production.

Features such as synchronizations and alternatives are provided to synchronize individual sequences across networked PLCs. On the other hand, jumps are provided for added flexibility.

Recipe parameters can be configured individually for each process step.

Finally, BRAUMAT adheres to the international ISA-S88 standard, providing a common set of terminologies and ensuring a consistent design philosophy.

Once downloaded, the recipe will execute even without the need of the Recipe Server, which is crucial during server maintenance works during a running production. It also provides a totally unproblematic recovery after power outages or system restarts, with no synchronization issues between the PC and the PLC.

Finally, the fact that PLCs are robust, industrial machines, designed for speed, makes them less prone to software glitches and ensures a lightning-fast system performance.

This allows for an improved design with increased safety, flexibility and transparency while lowering initial investment and ongoing operational costs (i.e. Total Ownership Costs). To read more about the benefits of adopting the ISA-S88 standard click here.

According to ISA-S88, the plant is structured hierarchically into Process Cells (e.g. Brewhouse), Units (e.g. Mash Tun), Equipments (e.g. Pre-Masher) and Control Modules (e.g. Valves). BRAUMAT implements these elements with the use of proven Technological Modules.

These standard Modules are parameterized and interconnected within BRAUMAT’s Engineering Environment without the need of programming, and allowing for simplified diagnostics at runtime.

Authorized personnel can intervene manually whenever necessary, while clearly defining the responsibility boundaries between automatic and manual operations.

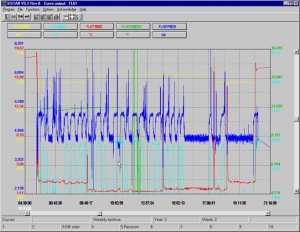

Every production order is stored in a production report (i.e. step protocol) composed of the entire recipe data including all process steps with its associated setpoints and actual values. Production reports, events, historical trends and system changes are all associated to a production batch, allowing tracing the final product back to its original components, as well as cross-referencing any relevant information.

Vertical Integration enables process data to flow from the plant floor right into your Enterprise Resource Planning System (ERP). All production data acquired by BRAUMAT can be fed into a SQL-Server database, providing a transparent interface to Manufacturing Execution Systems (MES) and/or your ERP for further analysis, reporting and execution. Additionally, production orders can be downloaded into BRAUMAT’s production scheduler for further execution. Read more…

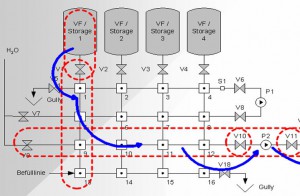

A highly advanced, standard and redundant Route Control System provides a complete overview of all pumps and valves involved in such routes, allowing for centralized, safe operation and efficient diagnostics of valve/pump activations and monitoring throughout the entire plant. Read more…

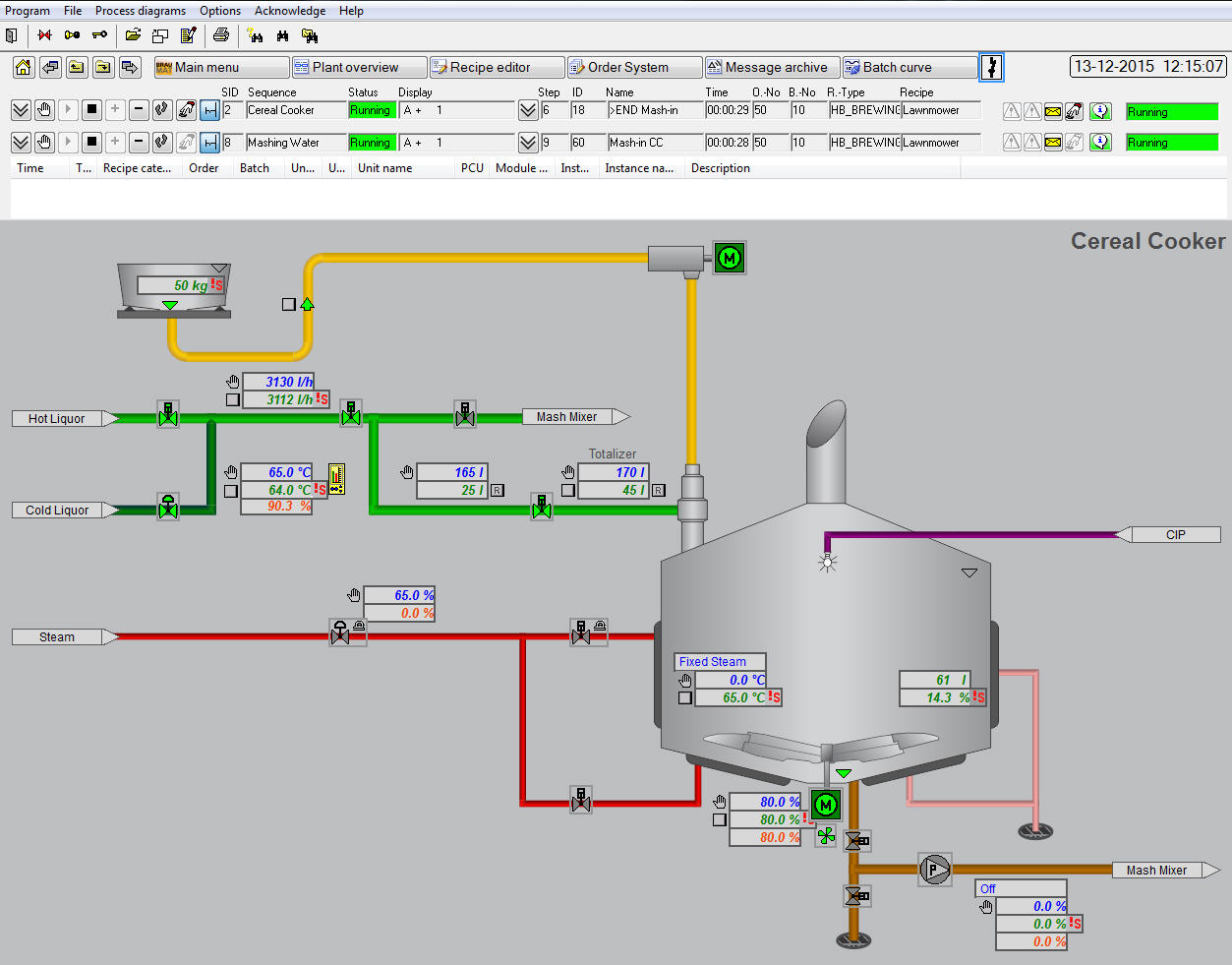

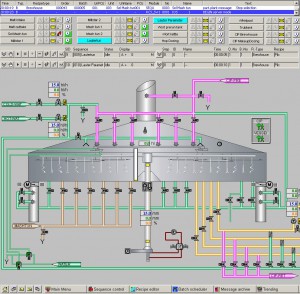

Would you rather have a simpler yet robust and highly standardized HMI that non-technical personnel would be able to learn quickly and use efficiently? Then BRAUMAT’s integrated standard HMI is for you.

On the other hand, if you’d rather have an HMI that provides all the bells and whistles to customize an HMI to your specific needs, then SIMATIC WinCC is for you.

Regardless of your choice, both solutions will provide you with all the functionality you will need to operate your Brewing plant, including among others:

- Detailed information on individual plant sections and its current production step.

- Software Controllers, which typically are used to replace the more costly hardware controllers.

- Standard faceplates (i.e. pop-up windows) for operation and diagnostics of BRAUMAT Technological Modules.

- Password protected user access.

- Event messages.