offer a high-quality, industrial design:

- Full-metal enclosure with high electromagnetic compatibility

- High level of dust protection and low noise generation through fan-controlled overpressure ventilation

- Continuous operation at ambient temperatures up to 40 °C (104 °F), at maximum configuration and without loss of power (throttling)

and integrated interfaces

make the SIMATIC S7-400 process controller

ideal for scaling up your Route Control System

as your production needs to grow.

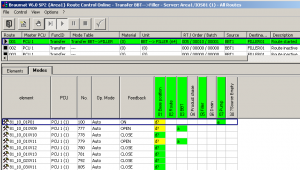

SIMATIC Route Control Features

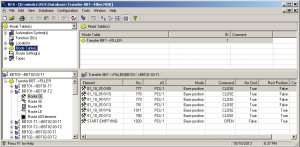

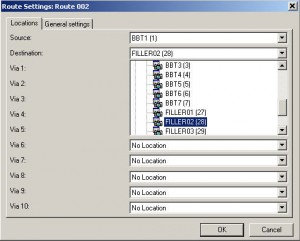

The Operator just needs to select the source where the product is stored and the destination where it is to be transported to. Optional routing alternatives or vias can be specified to allow for added flexibility. If the RCS finds more than one alternative, then the selection is done based on the shortest available route with the highest priority. Valves or Pumps in manual or maintenance mode will be identified before starting the route, allowing the operator to quickly verify the route’s availability.

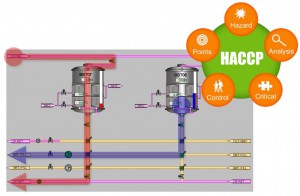

Another feature provides an additional level of security, where routes may be interlocked based on material type compatibility. For instance, a given route may be prevented from starting a product transfer, if any of the partial routes involved in the transfer process is dirty or still contains chemicals (e.g. from a running cleaning process).

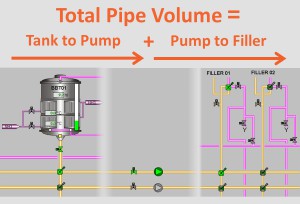

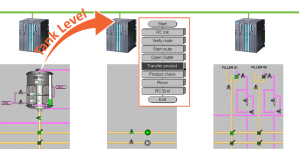

At runtime, if the product transfer takes place between BBT01 and FILLER01, then the corresponding embedded values will be added together to determine the total pipe volume.

Effective maintenance and diagnostic capabilities allow to react promptly in the event of a problem, thus minimizing downtimes and increasing plant availability.

RCS uses a standardized user interface with a straightforward operating philosophy. This consistency ensures safe and transparent plant operations throughout the process, while simplifying troubleshooting and diagnostics.

RCS uses a standardized user interface with a straightforward operating philosophy. This consistency ensures safe and transparent plant operations throughout the process, while simplifying troubleshooting and diagnostics.

Authorized personnel can intervene manually whenever necessary, while clearly defining the responsibility boundaries between automatic and manual operations.

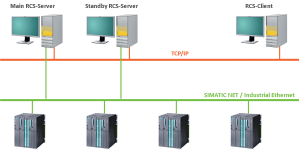

On the other hand, control tasks are carried out by the SIMATIC S7-400 PLCs. From a process control perspective, RCS-Servers only require connection to the PLC when starting a new route. When a new route is route, it is downloaded into the PLC, after which it runs independently from the RCS-Server.

Once downloaded, the route will execute even without the need of the RCS-Server, which is crucial during server maintenance works during a running production. It also provides a totally unproblematic recovery after power outages or system restarts, with no synchronization issues between the PC and the PLC.

Finally, the fact that PLCs are robust, industrial machines, designed for speed, makes them less prone to software glitches and ensures a lightning-fast system performance.

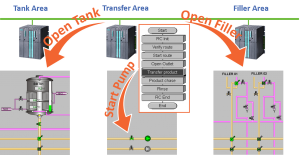

For instance, if PLC#2 is the one containing the transfer logic, i.e. the “brain” that determines the sequence of steps involved in carrying out a product transfer from the Tank Area, via the Transfer Area and into the Filler Area, then PLC#2 will only have to issue functional commands such as “Open Tank Outlet”, “Start Pump” and “Open Filler Inlet” while RCS will take care of activating the corresponding valves and pumps that have been configured behind those functional commands.

In this example, PLC#2 is completely unaware of the fact that the outlet valve for tank BBT01 is attached to PLC#1 and the inlet valve of FILLER01 is attached to PLC#3; this is all managed by RCS. And, as if this weren’t impressive enough already, any errors in the route are all reported back to PLC#2, enabling the transfer logic to take immediate corrective actions.

For instance, if PLC#2 is the one containing the transfer logic, i.e. the “brain” that determines the sequence of steps involved in carrying out a product transfer from the Tank Area, via the Transfer Area and into the Filler Area, then PLC#2 can read the contents of the currently selected tank. In other words, RCS automatically “encodes” data (e.g. Tank Level) from the route’s source (e.g. Tank BBT01), making it available to the transfer logic to make important decisions (e.g. end the product transfer when the Tank is empty).